Last Updated on January 21, 2023 by admin

Computer numerical control CNC is a process that can be used to create parts and products from various materials like plastic, metal, etc. When choosing a material for CNC machining, it is essential to consider the properties of the material and how they will affect the machining process. Some factors to consider are the hardness of the material, the ability to machine it too tight tolerances, and whether it is compatible with the lubricants and coolants used in the CNC machine.

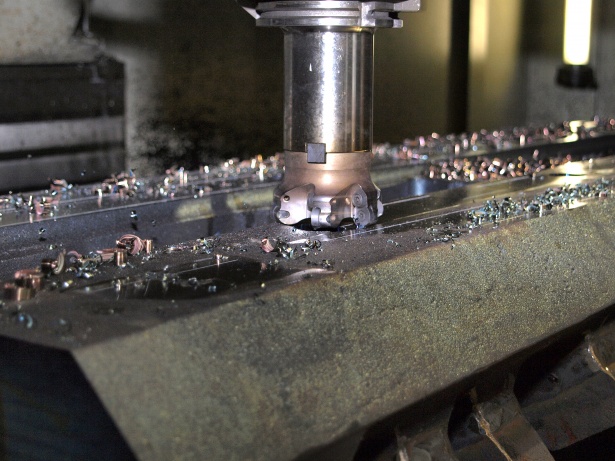

Photo by Daniel Smyth on Unsplash

Selection Process

The type of materials will depend on the type of CNC machining processes you select. Mainly three types of CNC machining processes are available:

- Milling machine – Milling machines can be used to device various materials, including wood, plastic, Aluminum, and even steel.

- Lathe machining- Lathes are best suited for round machining objects, such as pipes or spindles.

- CNC router – Routers are best suited for machining flat surfaces, such as countertops or tabletops.

Step 1: Identify the requirements

There are a few factors that need to be considered. The first is the material type that will be used. The most popular materials are Aluminum, brass, and steel. Each of these materials has its specific properties that will affect the machining process.

The second factor is the size and shape of the project. The dimensions of the project will dictate how much material is needed and what type of cuts will be required. The final factor to consider is the tolerance requirements. Tolerances will determine how precise the cuts need to be and what type of finish is required.

Step 2 – Identify potential material options

There are a variety of materials that can be machined using CNC technology, including metals (steel, Aluminum, brass), plastics (acrylic, polycarbonate), and composites (fiberglass, carbon fiber). Some standard options include Aluminum, brass, bronze, stainless steel, and titanium. For example, Aluminum is lightweight and strong but can be difficult to work with, while brass is easy to machine but not as strong as other options.

Step 3 – Select the most appropriate material

Many types of CNC materials are available on the market, and it is challenging to know which one is right for your project. The most appropriate material for your project will depend on several factors, including:

- the type of project

- the budget

- The required properties of the finished product.

Some of the most popular CNC materials include Aluminum, brass, and steel. Each has its advantages and disadvantages, so selecting the material that best suits your needs is important.

- Aluminum is the most lightweight and durable of the three materials, making it ideal for projects requiring high precision.

- Brass is more affordable than Aluminum but is also heavier and not as strong.

- Steel is the strongest material but also the heaviest and most expensive.

Factors to Consider For Material Selection

CNC machining is the best way to create high-quality parts and products. Let’s check the few factors that need to be considered while selecting the right CNC material.

You first need to consider the application or purpose of the part you’re making. What will it be used for? What needs does it have to meet?

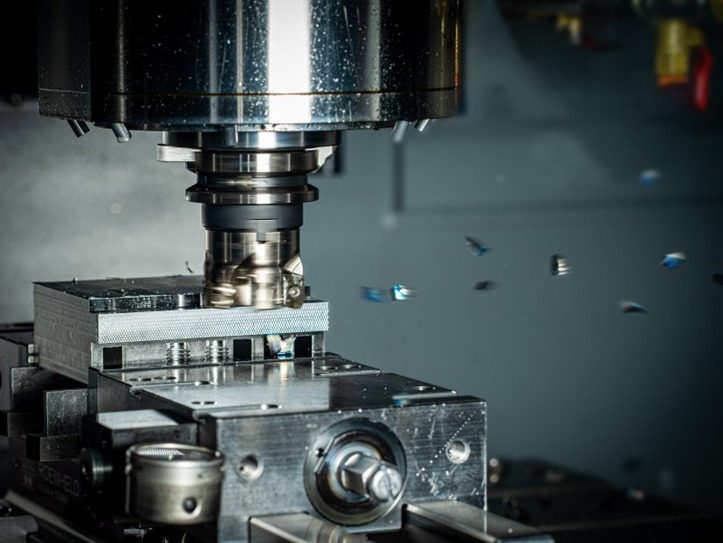

Photo by Daniel Smyth on Unsplash

The second factor is the material hardness. You need to make sure that the material is hard enough to withstand the rigors of the machining process.

The third factor is the material size. You need to ensure that the material is large enough to accommodate the size of your project.

The fourth factor is the material type. You should ensure that the material is compatible with the type of CNC machine you use. As an example, Aluminum is an excellent choice for machined parts that need to be lightweight and strong, like in the aerospace industry. Stainless steel is often used in food processing because it’s easy to clean and won’t corrode.

Purpose of the CNC Machined Component

The CNC Machined Component is used to create various shaped objects from various materials or products from a solid block of material. CNC machined components are used in a extensive range of industries and products. The main purpose of CNC machining is to create parts that are precise, accurate, and repeatable.

The components are used in many different industries like automotive, aerospace, medical, and consumer products.

- Medical industry: CNC is used to create parts for medical devices, implants, and prosthetics.

- Aerospace industry: To create parts for aircraft, satellites, and space vehicles.

- Automotive industry: CNC machining is used to make parts for cars, trucks, and other vehicles.

- Consumer products industry: The industry uses CNC machining to create elements for various products, including electronics, appliances, and toys.

Machinability

CNC machinability is a term that refers to how easy or difficult it is to machine a material using CNC technology. The level of machinability can vary depending on the specific material. In general, engineering materials tend to be quite machinable, meaning they can be easily cut, drilled, and shaped by CNC technology.

Physical Appearance

CNC machining can be used to create highly precise parts and components with a extensive range of shapes and sizes. In addition to its accuracy, Computer numerical control machining can also create parts with a variety of finishes and textures that can be used to improve the aesthetic appeal of the finished product.

Cost

The cost of CNC materials can vary depending on the material you need and the required quantity. The most common CNC materials are Aluminum, brass, and steel. CNC machining materials can range from Aluminum to plastic. Depending on the CNC project, materials will have different costs.

FAQ:

What are CNC Parts?

CNC machining parts are parts that have been machined using a CNC machine. CNC machines are computer-controlled machines that are used to create parts with high precision. CNC machines are often used to produce parts for medical devices, aerospace components, and other applications where accuracy is critical.

What is the best Aluminum for machining?

It depends on the specific machining application. Some factors to consider are the aluminum alloy type, the Aluminum’s hardness, and the desired surface finish. In general, however, aluminum alloys that are easy to the machine include 1100, 2024, and 6061.

What is CNC Milling?

CNC milling is a process where computer-controlled machine tools are used to remove material from a workpiece. The process can be used to create exact shapes and features and is often used in manufacturing parts for cars, airplanes, and other machines.

What are CNC Routers?

A CNC router is a computer-controlled machine related to the hand-held router used to cut various materials, such as wood, composites, Aluminum, steel, plastics, and foams. A typical CNC router has three axes: the X (left-right) axis, the Y (front-back) axis, and the Z (up-down) axis. Some CNC routers also have a fourth axis (rotary), which allows the cutting tool to rotate around the workpiece.

What is CNC Turning?

It is a machining process where a computer controls a workpiece’s rotation while holding it in place by a chuck. The computer allows for precise control of the speed and position of the workpiece, which results in exact and repeatable machining operations. The process can be used to create parts with a wide variety of shapes and sizes and is typically used for high-precision work such as creating medical devices or aircraft components.

What are the capabilities of CNC Machining Services?

CNC machining services can produce parts and components with high accuracy. The machines can create complex shapes and contours and work with various materials, including metals, plastics, and composites.

What materials can a CNC machine cut?

CNC machines can cut various materials, including wood, plastic, metal, and foam. They are often used in manufacturing and prototyping applications.

Which one is better between plastics and metals?

It depends on what you are looking for. If weight is a factor, then plastics would be the better choice. Plastics are usually lighter than metals and can also be molded into different shapes. Metals are generally stronger than plastics, so metals would be the better choice if strength is a factor.

What is the most common material for CNC tooling?

There is no definitive answer to this question as different materials can be used for CNC tooling depending on the specific application. However, some of the most common materials for CNC tooling include high-speed steel (HSS), tungsten carbide (WC), and polycrystalline diamond (PCD).

What is the most common material for CNC tooling?

It depends on the specific application. However, some of the most common materials used for CNC tooling include high-speed steel (HSS), tungsten carbide (WC), and polycrystalline diamond (PCD).

Apart from this if you are interested to know more about Perfect Canned Motor Pump then visit our Business category.